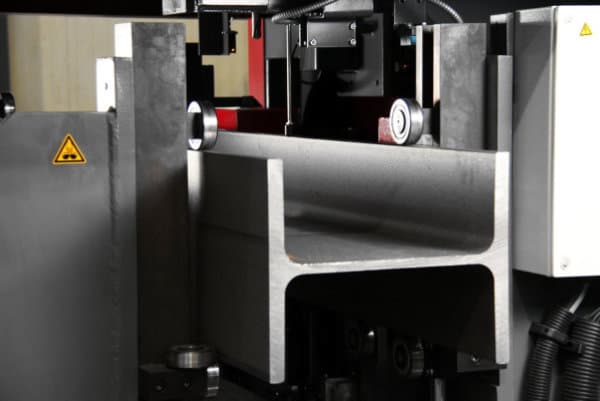

What is stronger C-channel or I-beam

AC Unit Mounted on Electrical Cabinet. The unit is located on the cabinet's High-Power (480v) side. It is located close to where the drives are installed. This allows for faster heat dissipation and keeps the cabinet's temperature stable. All axes have servo drives that are the main contributors to heat in the electrical cabinet.

Not every problem can be diagnosed with remote assistance. Mechanical issues or questions that require the human eye are still common. Voortman machines are shipped with high definition web cameras and software; allowing Voortman employees to directly experience the activity at the installation without the need to leave the office. The webcam has significant value in foreign countries or in situations where language might be a barrier to effectively communicate the issue.